CNAS-certified Lab

We have established our own CNAS laboratory in Shanghai, specializing in the verification of phase change energy storage technology and temperature control packaging solutions. Our team has 13 years of R&D experience, ensuring the provision of professional cold chain solutions to meet our clients’ most advanced and complex needs.

- Home

- CNAS-certified Lab

Meet Our Experts

Partner with our cold chain packaging experts and leverage 13 years of experience to meet your strict requirements for cold chain package safety and durability. We offer comprehensive cold chain solutions for the pharmaceutical, food, and transportation industries, all proven in our CNAS lab. Collaborating with us allows you to utilize our cutting-edge R&D technology to meet the latest challenges of cold chain transportation.

We Realize Your Cold Chain Packaging Concept

What sets Huizhou apart is our ability to transform your cold chain solutions from concept to reality. Our experienced team specializes in designing professional cooling and insulation solutions, which we validate in our CNAS laboratory to ensure their effectiveness.

Exhibition Hall

Our R&D center in Shanghai covers 1,400 m 2 and is equipped with CNAS and ISTA-standard laboratories. We focus on researching phase-change energy storage technology and temperature control packaging solutions, conducting testing and validation for cold chain temperature control packaging. Currently, we hold over 30 product technology patents.

Chemical Laboratory Area

Our chemical laboratory area is dedicated to the configuration and testing of cold storage agents. It operates under strict management standards in accordance with ISO 17025 and adheres to laboratory testing standards outlined in GB/T 34399-2017.

Climate Chamber Area

Our climate chamber area includes two specialized facilities:

Variable Climate Chamber: Designed for simulating high and low temperature environments to validate various environmental simulation solutions.

Controlled Climate Chamber (-35°C to 70°C): Used for validating constant temperature environment simulation solutions.

Solution Verification Room

Our solution verification room is equipped with low temperature freezer and ultra low temperature freezer for solution verification, internal material heating and cooling, and ice pack freeze-thaw tests to ensure that the solution is ultimately accurate and reliable.

Instruments & Equipment

Our facility is equipped with advanced instruments for precise material analysis and testing.

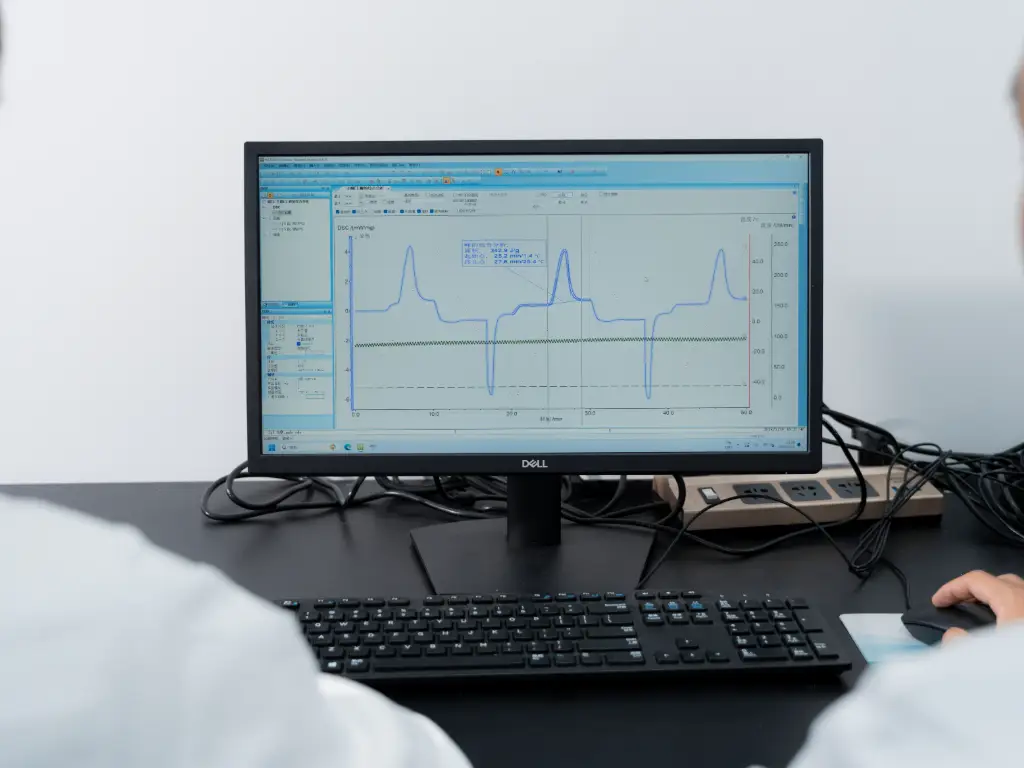

Differential Scanning Calorimeter (DSC): Accurately measures phase transition points and enthalpy values with cutting-edge technology.

High-Precision Balance: Capable of measuring up to 0.01 mg, ensuring high accuracy for material weight assessments.

Brookfield Viscometer: Used for dynamic measurement of transparent fluids, providing insights into viscosity properties.

Thermal Conductivity Meter: Evaluates the thermal insulation performance of materials, which is essential for cold chain solutions.

High and Low Temperature Test Chamber: Offers precise temperature control for simulating different environmental conditions.

Our R&D Center's Mission

With the booming cold chain logistics industry, our R&D center is committed to meeting the growing demand for complex cold chain packaging. By establishing a professional R&D team, we are able to provide customers with cold chain transportation solutions for various scenarios.

Our CNAS qualification further ensures the safety, compliance and availability of these solutions. This will help our customers reduce the risk of transportation losses and deliver goods to their destination intact every time.

Experience Huizhou's R&D and Manufacturing Center

Contact us today to schedule a visit and explore how we can bring your latest cold chain packaging ideas to life!